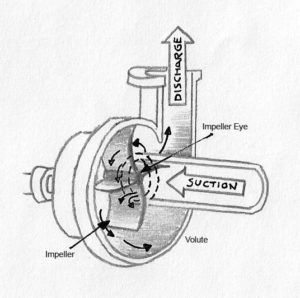

Centrifugal Pump

A machine that converts rotational energy from a mechanical driver into fluid velocity or kinetic energy and then into fluid pressure energy that moves liquids within a process. The energy changes occur in two main parts of the pump, the impeller and the volute. The impeller is the rotating part that converts driver energy into kinetic energy. The volute is the stationary part that converts kinetic energy into pressure energy. Liquid enters the pump suction and then the eye of the impeller. When the impeller rotates, it spins the liquid sitting in the cavities between the vanes outward and imparts centrifugal acceleration. As the liquid leaves the impeller eye, a low-pressure area is created at the eye allowing more liquid to enter the pump inlet. There are three main categories of centrifugal pumps:

1) Radial Flow: A centrifugal pump in which the pressure is developed wholly by centrifugal force.

2) Mixed Flow: A centrifugal pump in which the pressure is developed partly by centrifugal force and partly by the lift of the vanes of the impeller on the liquid.

3) Axial Flow: A centrifugal pump in which the pressure is developed by the propelling or lifting action of the vanes of the impeller on the liquid.