Brinell Hardness (HBW)

A measure of a metal’s hardness, which is determined by forcing a hardened steel ball (or a tungsten carbide ball for extremely hard materials) into the surface of a specimen. The indenting ball, which usually has a diameter of 10 mm (0.39 in.), is pressed into the sample using a predetermined load that is dependent on the relative hardness of the material. For example, a 500-kg load (4.9 kN or 1102 lbf) is used for softer metals and a 3000-kg load (29.42 kN or 6614 lbf) is used for hard metals. The load is applied for a defined time, usually 10 to 15 seconds, then the impression diameter is measured using a low-power microscope.

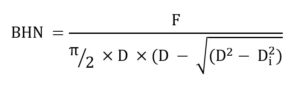

After the test is conducted, the Brinell Hardness Number (BHN) of the sample is calculated using the following equation:

where BHN is the Brinell hardness number; F is load in kgf; D is the diameter of the indenter in mm; and Di is the impression diameter in mm.