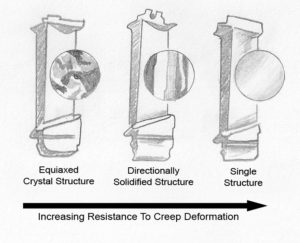

Directional Solidified Blade

The gas turbine blades with metallic crystals oriented perpendicular to the axis of rotation. Directionally solidified blades tend to offer improved ductility and thermal fatigue life performance and are more tolerant to localized strains, such as those found at blade roots.

The gas turbine blades with metallic crystals oriented perpendicular to the axis of rotation. Directionally solidified blades tend to offer improved ductility and thermal fatigue life performance and are more tolerant to localized strains, such as those found at blade roots.

These improvements over conventional polycrystalline blades allow directionally solidified blades to be applied at higher operating temperatures than standard blading. Directional solidification is performed in a vacuum chamber and involves pouring molten superalloy metal into a vertically mounted mold that is heated to metal melt temperatures and filling the turbine airfoil mold cavity from root to tip, or bottom to top. The bottom of the mold is formed by a water-cooled copper chill plate having a knurled surface exposed to the molten metal.

At the chill plate surface, crystals form from the liquid superalloy, and the solid interface advances until it reaches the top of the mold.