Force Feed Lubrication

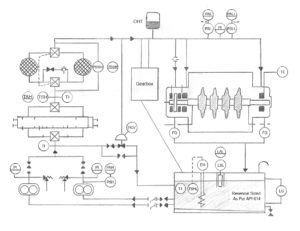

Rotating machinery operating at high speeds and heavy loads require a continuous flow of cool oil for lubrication and the removal of the heat developed by internal friction. In force feed lubrication (FFL) systems, a pump pressurizes the oil so that it can be supplied to individual bearings, gears, seals, etc. These systems can contain 1) pressure regulating valves; 2) coolers; 3) one or more oil pumps; 4) oil filters; and 5) a reservoir. Most FFL systems employ multiple orifices to accurately control oil flows to distinct components and safety instrumentation designed to trip the lubricated unit if pressures or oil levels drop below safe values. FFL systems can be found supplying oil to turbine generators, steam turbines, boiler feed pumps, process compressors, and gearboxes. There is a subtle difference between an FFL system and a closed-loop lubrication system: FFL systems are typically the sole suppliers of lubrication and cooling for a machine, while some closed-loop lubrication systems may be designed to simply recycle lubricating oil as a means of providing supplemental cooling and filtration.

Rotating machinery operating at high speeds and heavy loads require a continuous flow of cool oil for lubrication and the removal of the heat developed by internal friction. In force feed lubrication (FFL) systems, a pump pressurizes the oil so that it can be supplied to individual bearings, gears, seals, etc. These systems can contain 1) pressure regulating valves; 2) coolers; 3) one or more oil pumps; 4) oil filters; and 5) a reservoir. Most FFL systems employ multiple orifices to accurately control oil flows to distinct components and safety instrumentation designed to trip the lubricated unit if pressures or oil levels drop below safe values. FFL systems can be found supplying oil to turbine generators, steam turbines, boiler feed pumps, process compressors, and gearboxes. There is a subtle difference between an FFL system and a closed-loop lubrication system: FFL systems are typically the sole suppliers of lubrication and cooling for a machine, while some closed-loop lubrication systems may be designed to simply recycle lubricating oil as a means of providing supplemental cooling and filtration.